Electromechanical, NCFE Servo Press, Type 2157B

for joining processes with low force

Servo Press Tool

Features & Benefits

Measuring Range

| Measuring Range 1 | Measuring Range 2 | Order Key |

| 250 N | 50 N | 1 |

| 250 N | 100 N | 2 |

| 500 N | 100 N | 3 |

| 500 N | 250 N | 4 |

| 1000 N | 250 N | 5 |

| 1000 N | 500N | 6 |

| 1500 N | 100 N | 7 |

| 1500 N | 500 N | 8 |

Servo Press Application Examples

Process Controller maXYmos NC

Features & Benefits

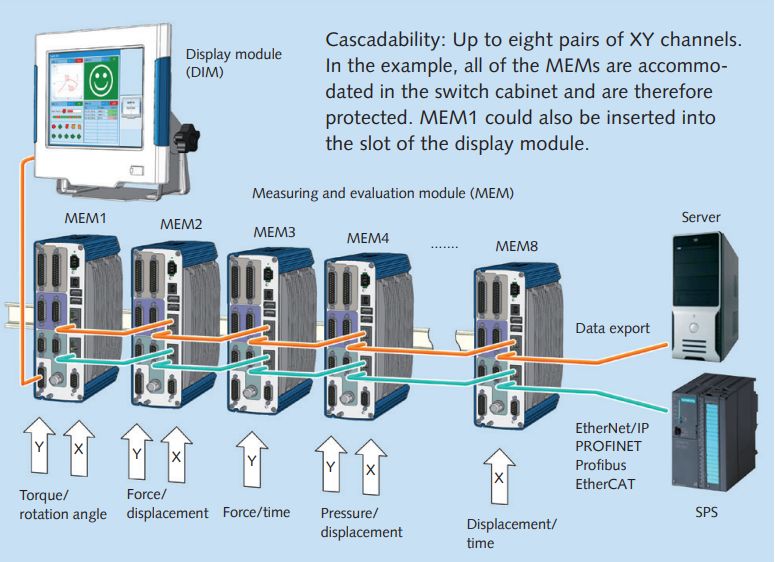

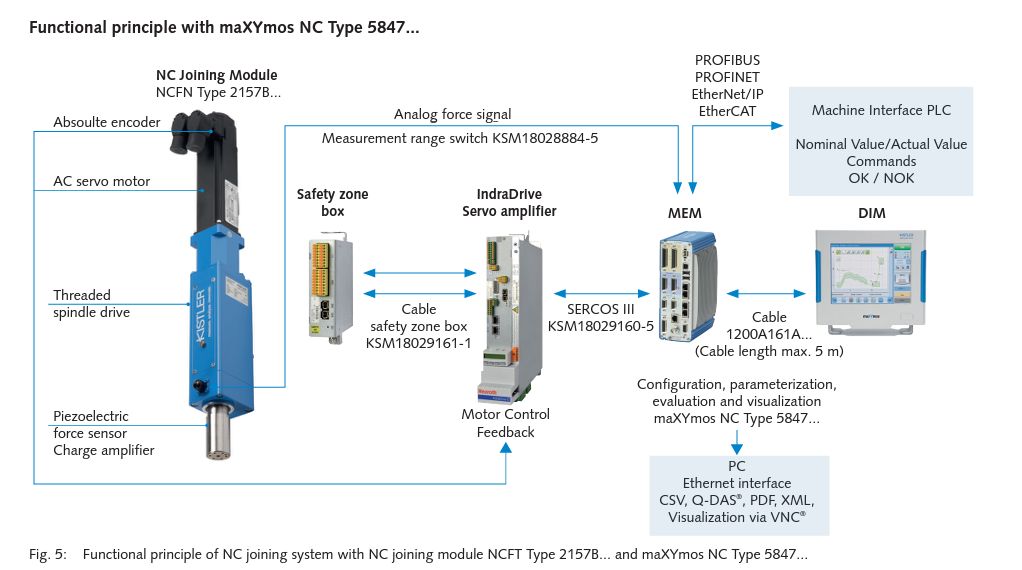

The maXYmos NC Measurement Evaluation Module (MEMs) controls, monitors, evaluates and documents XY characteristics for joining and press-fitting processes in combination with NC joining modules and the associated servo amplifier IndraDrive.

DIM Module

Features & Benefits

The maXYmos TL (Top Level) captures, analyzes and evaluates XY curves of two measurands that have to stand in a precisely defined relationship to each other. Such curves arise in applications such as