Servo Press System Overview

Kistler Servo Press Models

NCFH

Hollow Shaft Motor and Compact

• Force feedback control

• High measuring accuracy in two ranges

• High velocity

• Active compensation of process compression for exact

positioning

• No external PC with special software required

• Absolute encoder, eliminates reference point determination

• Low maintenance

NCFC

Weight Optimized Servo press

- NC joining module NCFC, weight optimized and compact NC joining module

- Measuring range: 55 or 80 kN

- 200 mm stroke

- Weight with brake 47.1 & 67.3 kg for the two sizes

maXYmos – XY process monitoring system

maXYmos BL

Monitor sophisticated evaluation curves

- 16 Measurement Programs

- 5″ Colorful IPS display with touch operation and live view

- USB-Host for exports, backup/restore, or text/number input

- Basic evaluations: Box, Line, No-Pass, Get-Ref, Calc, Envelope

- Reverse compatible to former 5867B (specific limitations apply)

- Measurement function Y(X), Y(t), Y(X,t) or X(t)

- Evaluation via UNI-BOX, LINE-X, LINE-Y, ENVELOPE,

NO-PASS (real-time threshold)* - 4 evaluation elements per curve

- Up to 8,000 XY value pairs per curve

- Short evaluation time, up to 10 parts/second

- Ethernet TCP/IP for web UI and data transfer

- EtherNet/IP, EtherCAT, PROFINET for process values and

control* - Dig. IO (24 V) for control and results

- 2 real-time switching signals for X and Y threshold*

- Sensor X: ±10 V, potentiometer, or incremental*

- Sensor Y: Piezo or strain gauge and ±10 V*

- Front panel, table or wall mounting

- Info pages on the diagnosis of the cause of NIO

- Internal part ident generator selectable

- Warning and alarm messages

- Access protection for different user groups

- Licensed functions*

- Connections and security (incl. LDAPS / AD)

- Extended evaluations (6 EO, GET-REF, CALC)

- IIoT connectivity via OPC-UA

- Sequencer mode

- Functionality depends on hardware and licences

maXYmos TL

Monitor sophisticated evaluation curves

- 108 measurement programs and 20 master programs

- Curve capture according to Y=f(X), Y=f(X,t), Y=f(t), X=f(t)

- Curve evaluation with NO-PASS, LINE-X, LINE-Y,

UNI-BOX, ENVELOPE, GET-REF, CALC, GRADIENT-Y,

GRADIENT-X, HYSTERESIS-Y, HYSTERESIS-X,

TUNNELBOX-X, TUNNELBOX-Y, SPEED, AVERAGE,

BREAK, INFLEXION, INTEGRAL, DIG-IN, DELTA-Y,

TRAPEZOID-X, TRAPE-ZOID-Y, TIME, DISPLACEMENT

RANGE, FORCE RANGE, PASS-THROUGH BOX - Up to 10 evaluation objects (EOs) per curve

- Dynamic referencing of evaluation objects in X and Y

directions - Measurement curve with up to 8,000 XY value pairs

- Access via web-browser using encryption

- EtherNet TCP/IP for measurement data and remote

maintenance - Choice of bus types available via menu: PROFIBUS DP,

EtherNet/IP, PROFINET, EtherCAT - Dig-IO (24 V) for control and results

- 2 switching signals on X or Y threshold

- 2+1 USB for USB stick and notebook

- Channel X: Pot, ±10 V, LVDT, incremental, SSI

- Channel Y: Strain gauge, ±10 V, ±10 V (2 measurement

ranges), and piezoelectric sensors - Multiple data export formats, e.g. Q-DAS, QDA9,

IPM 5.0, XML, CSV, PDF - Desktop, wall or front panel mounting; can be repositioned

in a few easy steps - Informative NOK cause diagnosis, process value trend

patterns, etc. incl. warnings and alarms - Process value table with free choice of contents

- Selected process values for the curve graph

- Acces protection with configurable levels of access

- Display module (DIM) with 10.4″ color touch screen and

front-mounted USB slot - Sequencer mode (logical sequence control)

maXYmos TL ML - FDA and MDR conform process monitoring

Licensed functions - Connections and security (incl. LDAPS / AD)

- Multipoint calibration

- IIoT connectivity via OPC-UA

- Audit trail

- Extended evaluation

What is a servo press?

Kistler Assembly servo press is a proven custom press application solution with many applications in the automotive, medical, electronics, etc. with force, torque & displacement built-in monitoring & data collection – interfaces with multiple software -.

Application Examples

Examples of servo presses include electromechanical joining systems to produce joints of various types using processes such as press-fitting, caulking, riveting, embossing, clinching, and so on. They are used in automatic production plants as well as manually controlled workstations.

These systems are used frequently throughout the automotive industry, for applications such as New Energy Vehicles (NEV), engine and transmission assembly, steering systems, chassis, brakes, injection pumps and airbags, and also for various electric motors such as those for windshield wipers. Additional key application areas include the medical devices sector, the electronics, and domestic appliances industries, and power tools.

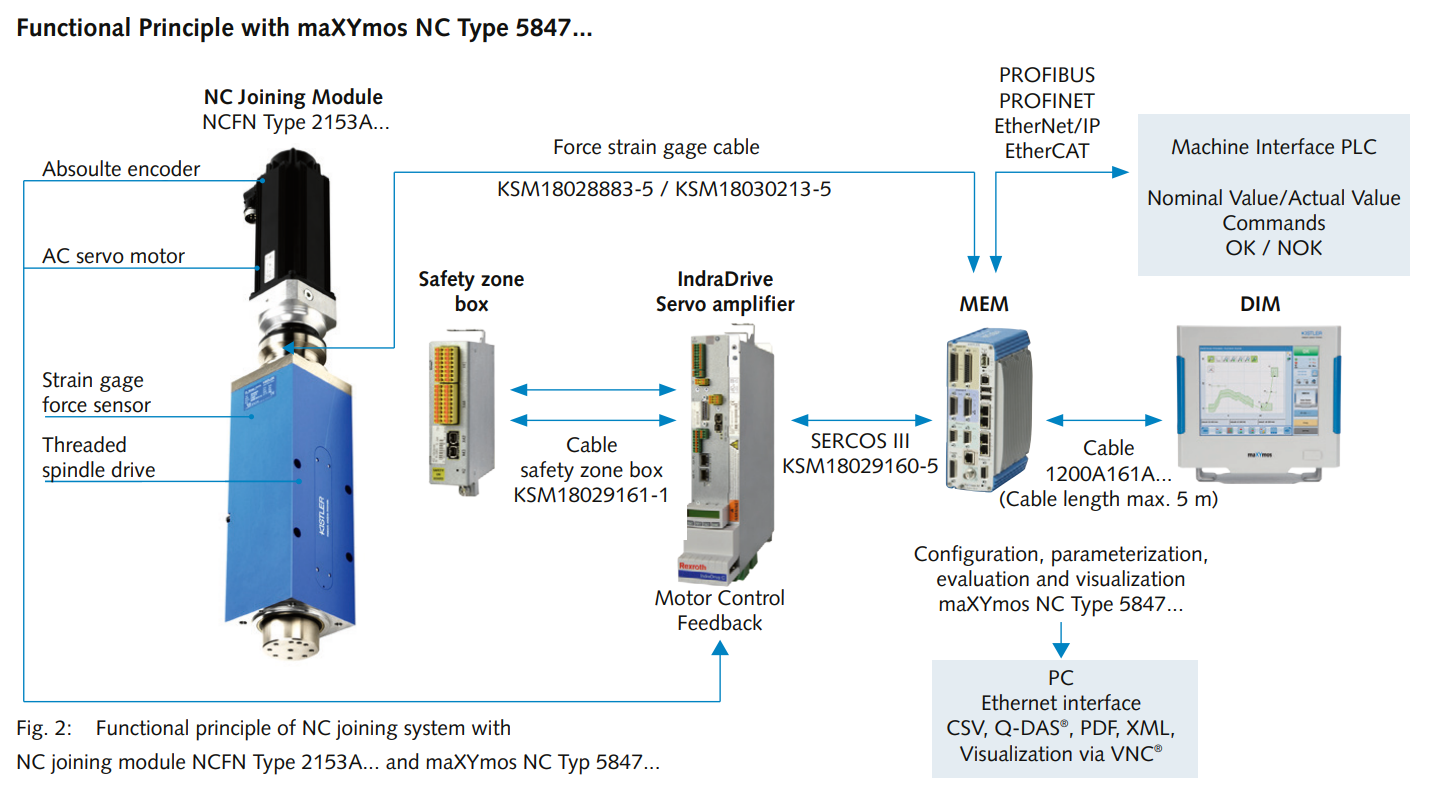

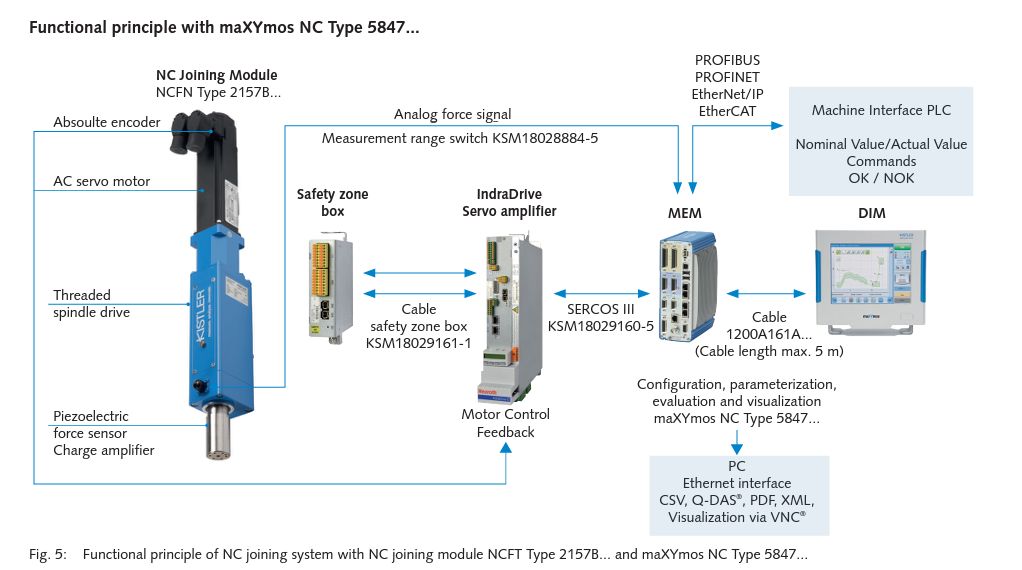

A joining system such as a servo press typically comprises a joining module (also known as a “joining spindle”), a servo amplifier, and a force-displacement evaluation unit. Process monitoring systems are used for quality assurance. On the basis of data from force and displacement sensors, they evaluate and document the force-displacement profiles (XY curves) for joining and press-fit processes.

As well as monitoring the process, it is also possible to control it in real-time. Various standard functions are available for these purposes, including force cutoff and control, gradient and inflection point detection, as well as a signal or position-based joining.

Why the Kistler servo press for assembly automation applications?

Kistler Servo Presses are rated 100% of rated force. For example a 100 kN model – you can run it at 100 kN. There is no derating.

Easy Programing – See video on how simple it is to setup a program

- No PC required

- Software – maXYmos Offline Tool – (Change joining profile, import csv files, off-line evaluation of objects, backup)

- PC Software (Backup, restore, firmware, analysis of curve, easy statistics)

Plug and Play Data Collection

- USB Data logging, Hard drive, VNC, fieldbus

- Standard formats- CSV, XML, PDF, PVT

- Q-DAS, QDA-9 ,IPM (Integrated Process Management), QualityWorX

What are safety options available on the Kistler Servo Press?

- Safe-Torque-Off (STO) is standard on all models

- Safety Zone Box

Leading fieldbus as standard offer

- Ethernet/IP

- Profinet / Profibus

- EtherCAT